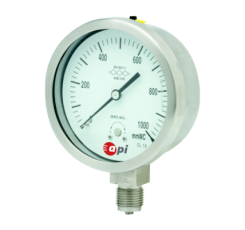

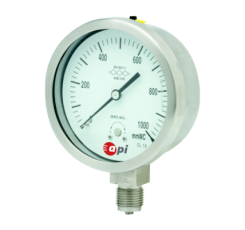

PRODUCT SPECIFICATION

STANDARD VERSION [CODE : 1]

Dial size: DN100 / DN150 / DN250

Range: -1...0...1,600 bar

Mounting pattern: Direct, Bottom connection

Process connection: ½" NPT (M) /½” BSP (M)

Ingress protection: IP 67

Execution: Dry but fillable

Case & Ring material: AISI 304 (Bayonet type)

Bourdon tube & Shank: AISI 316L

(Shank welded directly to case)

Movement mechanism: AISI 304

Dial: Aluminum, black graduation on white background

Pointer: Micro-zero adjustable, aluminum, black powder coated

Gaskets, Blow off disc & filling plug: Neoprene

Window: Shatterproof safety glass

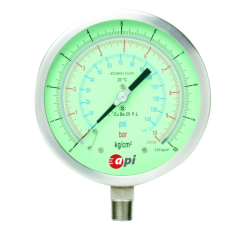

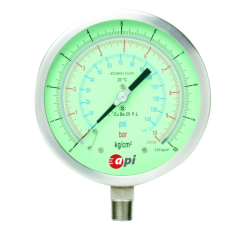

LIQUID FILLED VERSION (GLYCERIN) [CODE : 2]

Ambient temperature: -20…+65°C

Dampening liquid: Glycerin 99.7

LIQUID FILLED VERSION (SILICON OIL) [CODE : 3]

Ambient temperature: -40…+65°C

Dampening liquid: Silicon DC 200

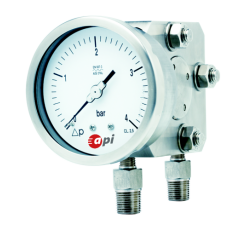

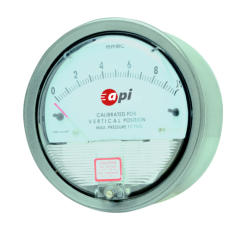

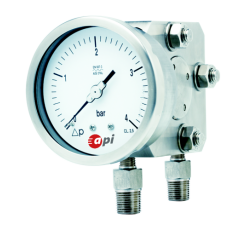

MAIN FEATURES

All SS measuring system

Socket-case, direct welded

Dry but fillable/liquid filled

SUGGESTED APPLICATIONS

Liquid & gaseous mediums

Corrosive environments

Oil & Gas applications

Chemical & Petrochemical

Food & Beverages

Nuclear power plants

BASIC DESCRIPTION

Sensing element: Bourdon Tube

(<100 bar: C-type, >100 bar: Helical)

Accuracy: ±1.0 F.S.D.

Ambient temperature: -40…+65°C

Service temperature: 200°C version CODE 1

100°C version CODE 2 & 3

Steady pressure: Up to FS value

Fluctuating pressure: Up to 90 of FS value

Over-pressure: 1.30 x FS value ≤ 100 bar

1.15 x FS value ≥ 100 bar

Weld joints: TIG argon arc welding

5 Point Calibration Certificate