Application

For direct, permanent installation in pipelines

For flowing, pure and aggressive media

Chemical process industry

Petrochemical industry

Special Features

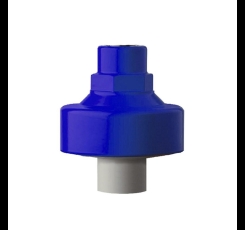

Completely round, no corners and edges

For direct installation between two flanges

Wide choice of special materials

Heatable version available

Description

Process connection

Sealing face, Form B1 or ASME RF 125 ... 250 AA For flanges following ASME B 16.5, 1", 2", 3", 4"

Nominal size: see drawing and tables on datasheet

Pressure rating

Class 150/300

Pressure ranges

Preferably mounted to pressure gauges NS 63, 100, 160 or pressure transmitters, Pressure ranges 0 ... 15 to 0 ... 600 psi

Housing and material of wetted parts

Stainless steel (AISI 316L)

Measuring instrument connection

Pressure gauge or transmitter directly welded, process pressure transmitter with threaded adapter

Options

Process connection

Larger nominal sizes

Other flange connections on request

Sealing faces per EN 1092-1, form B2 or per ASME B 16.5, RF 125 AA, 500 AA, RFSF; EN 1092-1 groove and tongue; projection and recess; ASME B 16.5 snap ring groove form RJF (limited for special materials, please request)

Flame arrester approved for zone 0

Material of wetted parts

Stainless steel 316TI, 316, 321, Monel, Hastelloy B3, C22, C276, tantalum

Measuring instrument connection

Capillary, when ordering please specify: length of capillary

Cooling tower (for directly mounted gauge when fluid temperature > +284°F)

Capillary

Custom lengths between 3 and 25 ft.

Soft polyethylene or PTFE armour