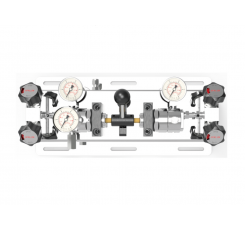

Features

Suitable for uninterrupted air supply one end is exhausted and automatically switches to the other end

Priority gas source can be set by using the gas source priority selector handle

Prototype WR11 pressure reducing valve for corrosive and toxic gases

WV4H diaphragm valve with two 3-way valve as a prototype, fewer connections

Inlet mounted 20 µm filter element

Oxygen environment options available

Output pressure is factory set within a certain range

Technical Data

Max Inlet Pressure: 3500 psig

Outlet Pressure Range: 85~115, 135~165, 185~60, 0~215, 235~265 psig

Internal Component Material

Valve seat: PCTFE

Diaphragm: Hastelloy

Filter mesh: 316L

Working Temperature: -40~+74 °C (-40~+165 °F)

Leakage Rate (Helium)

Inside the valve: ≤1x10-7 mbar l/s

Outside of valve: ≤1x10-9 mbar l/s

Connection: no visible bubbles

Discharge coefficient (Cv)

Pressure relief valve: Cv=0.2

Diaphragm valve: Cv=0.17

Parent port

Entrance port: 1/4 NPT

T export: 1/4 NPT

Pressure gauge port: 1/4 NPT

Principle of Operation

DCOS11 series switching device contains two independent pressure reducing valves. The left and right outlet pressures are adjusted by operating the linkage stem. When the left side increases, the right side decreases and air is supplied to the left side; when the right increases, the left side decreases and air is supplied to the right side

Empty the depleted side of the air supply by closing the inlet diaphragm valve and opening the pressure relief diaphragm valve, the replace with a new air supply

Priority air supply can be selected by turning the switching handle

Cleaning Technics

Standard (WK-BA)

Welded joints are cleaned in accordance with our standard cleaning and packaging specifications and are to be ordered without suffix

Oxygen Cleaning (WK-O2)

Product cleaning and packaging specifications for oxygen environment are available, which meet ASTM 93 C cleanliness and are ordered by adding O2 after the order number.